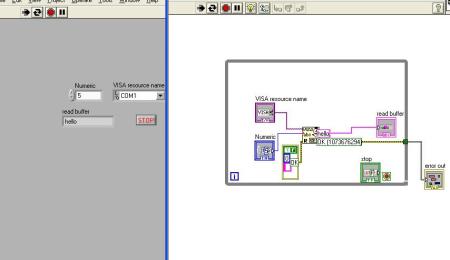

I am going to write about the GUI that I developed for sending data to my PIC development board. I used Liberty BASIC Gold version to develop this GUI.

You may download the demo version for free at http://www.libertybasic.com/. However, there are certain limits for the software and you have to register for a Gold version to enjoy all the features of the software. The programming window of the software looks like the one shown in the picture below.  There are tutorials available in the software which may be accessed as shown in the picture below.

There are tutorials available in the software which may be accessed as shown in the picture below.  You may learn to open a GUI window, add buttons and consequently handle events upon button click using the simple tutorials. These are essential elements for our COM port recipe. When you are done with the tutorials, you would be capable enough to design a small interface as shown in the picture below:

You may learn to open a GUI window, add buttons and consequently handle events upon button click using the simple tutorials. These are essential elements for our COM port recipe. When you are done with the tutorials, you would be capable enough to design a small interface as shown in the picture below:  Once you are done adding buttons, you must add a functionality to the buttons. For eg: I have added the close window option to Quit button. I am sending a string of information to my controller when I press either of the Forward, Reverse or Neutral buttons.

Once you are done adding buttons, you must add a functionality to the buttons. For eg: I have added the close window option to Quit button. I am sending a string of information to my controller when I press either of the Forward, Reverse or Neutral buttons.

The algorithm for the same is as follows:

1) Open COM port

2) Send string

3) Close COM port.

Close button press event handle

Note: You have to close the event handles properly once you are done with handling the event of a button press or your code may end with bugs.

The algorithm at the PIC microcontroller end to receive ASCII string from your computer is as follows:

1) Initialise ports and Set the Baud rate

2) If data received, read the data.

3) If string x is received, move forward

4)If string y is received, move reverse

5)If string z is received, move to neutral position

6) Go to step 2

Please note that I am trying to control a servo motor through serial port. If you would like to know the operation of a servo motor, please refer to the following link.

I used the MikroC compiler to write the code for serial port communication and servo motor control.

unsigned short i;void main(){TRISB = 0x00;USART_init(19200);while(1){ if (USART_Data_Ready()){i = USART_Read();i = i-48;if( i ==1){PORTB = 1;delay_us(1500);PORTB = 0;delay_ms(18);delay_us(500);delay_ms(1000);}else if(i==0){PORTB = 1;delay_us(1250);PORTB = 0;delay_ms(18);delay_us(750);delay_ms(1000);}else if(i==2){PORTB = 1;delay_us(1750);PORTB = 0;delay_ms(18);delay_us(250);delay_ms(1000);}else{}}}}

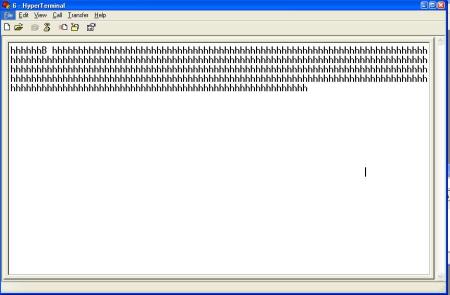

Please note that the baud rate was 19200 bps, 1 stop bit, no parity, no hardware control and the number of bits transmitted was 8.

When you are done coding your PIC, you may create an exe file for your application as follows:  You may download the GUI that I developed from the following location.

You may download the GUI that I developed from the following location.

You may also have a look at my video of operating my servo motor through serial port.

Posted by yamanoorsai

Posted by yamanoorsai

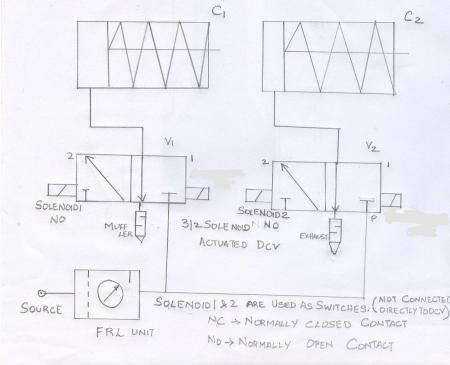

The single acting cylinders could be replaced by two double acting cylinders. An interlocking circuit where one cylinder remains retracted while the other is extended could also be developed easily. This circuit could be controlled for any timing sequence altering the delay between the extension of the cylinders. This is controlled in the program.

The single acting cylinders could be replaced by two double acting cylinders. An interlocking circuit where one cylinder remains retracted while the other is extended could also be developed easily. This circuit could be controlled for any timing sequence altering the delay between the extension of the cylinders. This is controlled in the program.

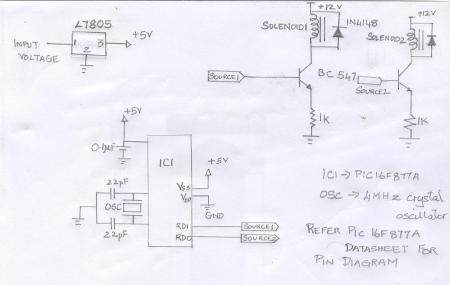

The Pic 16F877A data sheet can be downloaded from the

The Pic 16F877A data sheet can be downloaded from the