I had a long chat with one of my friends regarding microcontroller applications and the like.

It never occurred to me that we spend thousands on buying different components for our hobby projects and we discard them after their intended use or construct a different one for another application.

A classical example of using an electronic circuit board on a longer run is your first microcontroller development board. Be it AVR or a PIC microcontroller, you are going to re-use them for several hobby projects. Why not develop it as a standard platform?

There are people who sell development boards for PIC and AVR microcontrollers in the market. They provide you with standard interfaces to learn from scratch. For e.g LED Blinking, Seven Segment LED interface, LCD interface, Stepper Motor Driver, Servo Motor Driver etc. One can develop them for himself/herself, step by step.

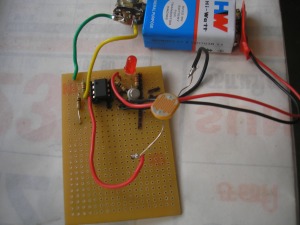

The insert picture shows a PIC 16F877A board developed by me for my hobby projects. It has got the ubiquitous LED interfaced to it. Any hobbyist tests his/her microcontroller board with a standard LED blinking program to start with.

By developing one such board, I learnt interfacing the above mentioned examples. I developed all the standard drivers required for the components, myself. One day, I am planning to bring all the applications together as a product!

Why not try one for yourself?

Posted by yamanoorsai

Posted by yamanoorsai