If you haven’t used the Eagle PCB design tool lately, you will be surprised to learn that it has underwent a major update since it was acquired by Autodesk.

Eagle’s license model has been switched over to a subscription service and I am liking the experience so far. I am able to get the latest updates of the software (unlike earlier, the updates are quite frequent). I am currently using Eagle 8.5.x and it comes with the “Push and Shove” feature that automatically pushes signal traces while routing your PCB.

PCB Outlines

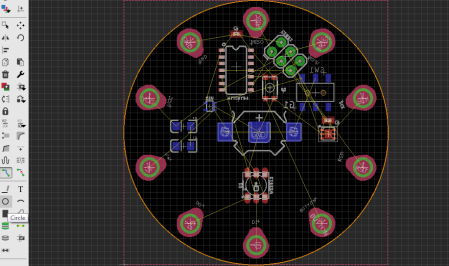

I was working on a circular PCB for building something like a fidget spinner. I assumed that I could draw circular PCB outlines by drawing a simple circle.

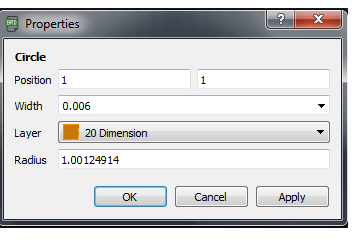

Circle feature in Eagle PCB

Being able to draw circular outlines can make your life easy. For example: You could draw a random circle and specify its radius, center etc (similar to Mechanical CAD tools).

It turns out that the software considers this an error. When I started to route the PCB, the automated DRC check ignored glaringly obvious errors.

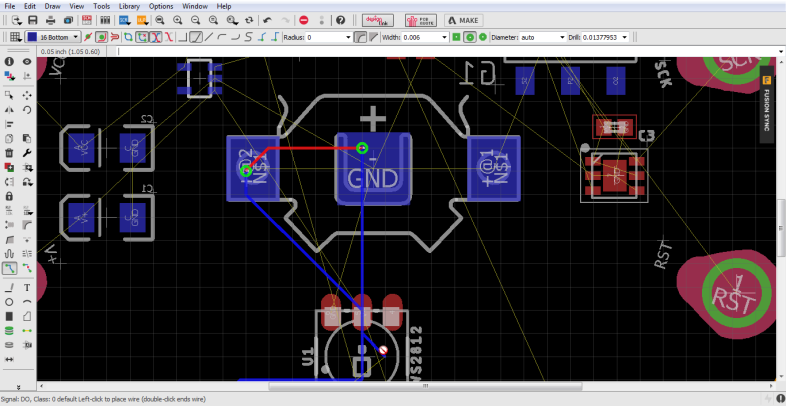

Errors resulting from the Circular Outline

In the above snapshot, you will note that I am able to route traces over PCB pads and the cursor indicates bad news.

After wasting some time, I found out from this forum thread that I need to draw my outline using arcs.

In Eagle, drawing an arc is a three step process:

- Specify the starting point

- Move the cursor to specify the arc radius

- Draw the arc

It is definitely confusing and imagine drawing a “closed circle” using arcs. It can be frustrating.

I eventually managed to find a simple solution that involves combining arcs to draw circular outlines. Check it out!

I am no video expert. I made this video using basic screen capture tools. I look forward to hearing your tips on improving the video.

I really hope Autodesk simplifies creation of non-standard outlines. Did you have a similar experience? Drop your thoughts in the comments section!

My design is off to OSH Park. What manufacturing house do you use for your designs? I will share my build in upcoming blog posts.

Posted by yamanoorsai

Posted by yamanoorsai